- See the following.

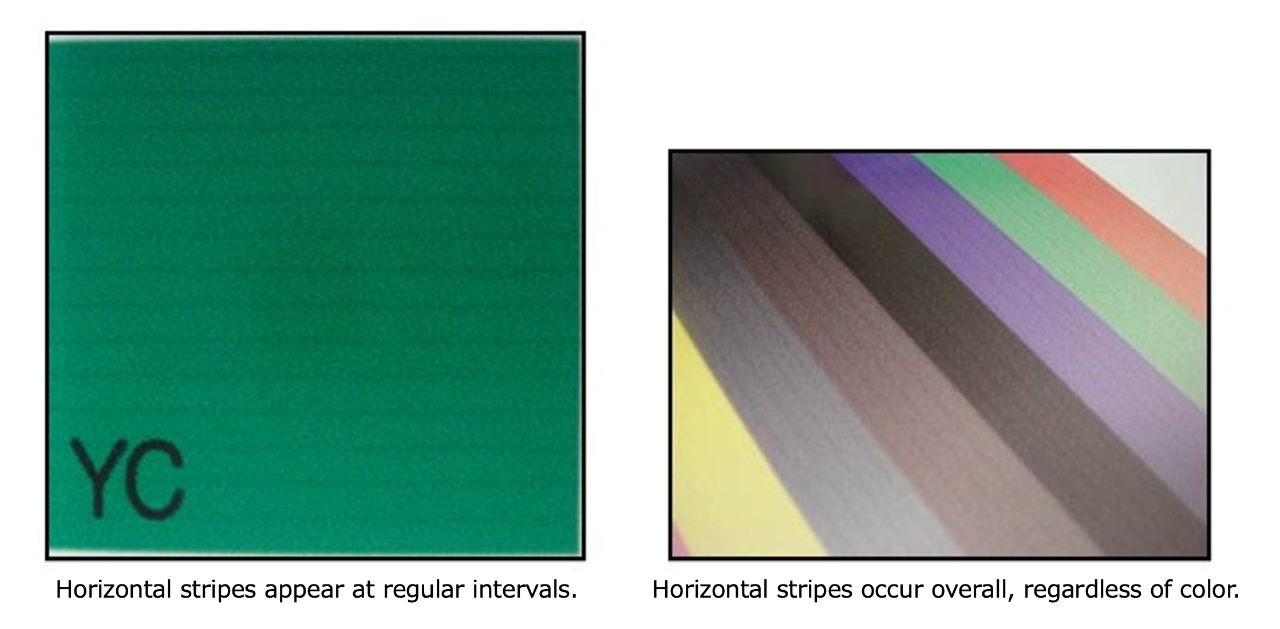

When the media feed amount is misaligned, it results in horizontal stripes at regular intervals,

as shown in the figure below.

Refer to the "Operation Manual" for each model, perform media correction [FEED COMP.] and adjust the media feed amount accordingly.

* After changing the type of media or adjusting the heater temperature, please perform

media feed adjustment.

* When printing with a take-up device, set the media first and then perform media correction.

2. If the method in step 1 does not result in improvement, please proceed with maintenance.

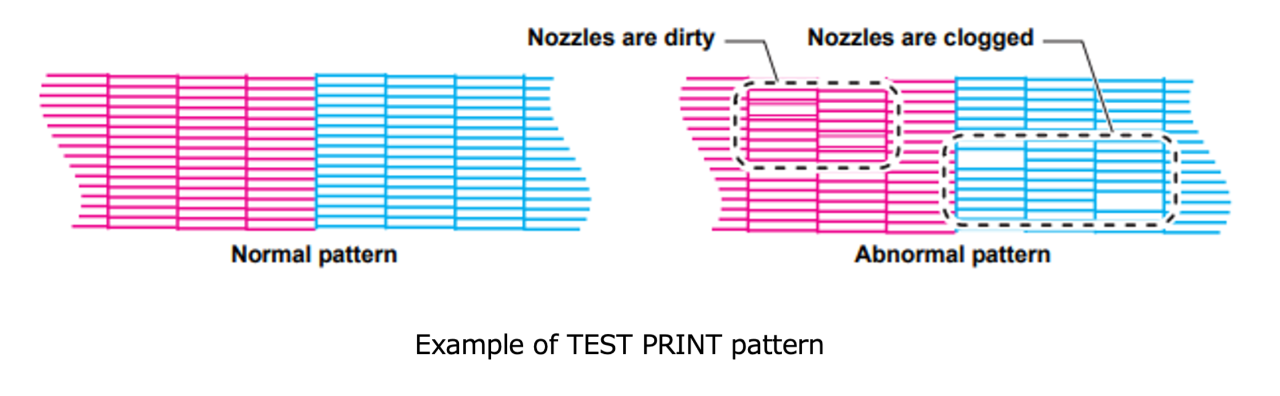

When there is nozzle missing or deflection in test print, it can lead to issues with print quality,

such as stripes and unevenness.

After referring to the maintenance section in the Operation Manual and the following FAQ,

please perform maintenance to resolve the firing issue.

JV400LX Series

FAQ: TEST PRINT is not printed successfully

3. If the methods mentioned in step 2 do not improve the situation, please change the printing conditions.

In the heater temperature is low and the media is not adequately warmed, or if the pass count is low, improper printing conditions may lead to occurrences of beading or banding.

* Beading refers to the phenomenon where ink droplets that have landed first are not fixed before the next ink droplets land, causing adjacent dots to merge together.

When beading occurs, it can result in a mottled appearances, or cause banding across the print at intervals between passes.

Please try the followings.

- Increase the temperature of the heater.

* Please refer to the following FAQ for instructions on how to adjust the heater temperature settings.

JV400LX Series

FAQ: How do I set the heater temperature?

- Increase the number of passes to gradually deposit ink.

- If the printing direction is bidirectional, set it to unidirectional to allow for drying time.

- If printing at high speed, disable high-speed printing to allow for drying time.

- Set the drying time for each scan to allow for drying time.

- Adjust the ink volume according to the media.